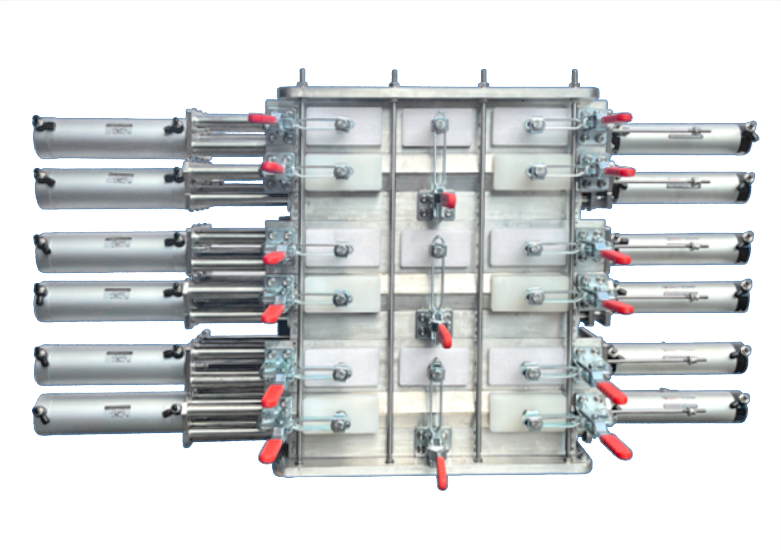

Continuous Pneumatic Iron Remover

The JH-LX series continuous pneumatic iron remover is widely used in industries such as electronics, building materials, chemicals, coal, food, pharmaceuticals, and refractory materials. It is suitable for continuous and automatic iron removal equipment designed specifically for production lines that require continuous operation of dry powder or granular materials.

Main features:

1. Installation of circular and square pipeline positions for gravity free falling. Typical suitable installation locations are: vibrating screen, rotary valve, feeding station, feeding mechanism, downstream of crusher; Upstream of packaging machines and shredders; And other required installation locations. Can work continuously and uninterrupted for 24 hours or more.

2. Automatic cleaning of iron filings. Users need to configure air pressure>2000Pa and flow rate>400m ³/ The dust collector of H timely collects the cleaned iron filings and dust.

3. Use compressed air with a dew point of -20 ℃ and a pressure of not less than 0.5MPa as the power source (if used in electronic grade products, compressed air must be oil-free and purified). PLC control, automatic control system with touch screen input.

4. The maximum surface magnetic field strength of the ordinary series is 12000-13000GS, and the working temperature is ≤ 80 ℃. If necessary, strong magnetic materials with a maximum working temperature of 250 ℃ can be provided. This equipment can be adapted according to the characteristics of the material: JH-B standard cylindrical core or JH-L spiral magnetic field cylindrical core, achieving the best cost-effectiveness and iron removal effect. According to tests, this machine can effectively remove iron powder with a particle size of more than 100 microns (about 150 mesh).

5. The specifications of the JH-LX series continuous pneumatic iron remover are;

1) JH-04B - Each unit is equipped with 2 sets of standard continuous pneumatic iron removal units, each unit has 16 sets of iron removal combinations in four layers, and the entire unit has a total of 8 layers and 32 sets, driven by four pairs of cylinder banks. Boundary dimension: 1766mm × 360mm × 768mm.

2) JH-06B - Each unit is equipped with 3 sets of standard continuous pneumatic iron removal units, each unit has 16 sets of iron removal combinations in four layers, and the entire unit has a total of 48 sets in 12 layers, driven by six pairs of cylinder banks. Boundary dimension: 1766mm × 360mm × 1008mm.

3) JH-12B - Each unit is equipped with 6 sets of standard continuous pneumatic iron removal units, with 16 sets of iron removal combinations in four layers. The entire unit has a total of 24 layers and 96 sets, driven by 12 pairs of cylinder banks. Boundary dimension: 1766mm × 360mm × 1722mm.

4) JH-06X - Special for ultrafine powder, each equipped with 3 sets of dedicated continuous pneumatic iron removal units, each unit has 2 layers of 9 sets of iron removal combinations, and the entire unit has a total of 6 layers of 27 sets, driven by 6 pairs of cylinder banks. Boundary dimension: 1842mm × 360mm × 1008mm.

(The external dimension parameters are for reference only, and the specific details shall be subject

to the factory inspection report or order contract)

6. According to user requirements, non-standard designs can be provided to meet different needs.